Sodium-ion battery manufacturing principles and advantages and disadvantages

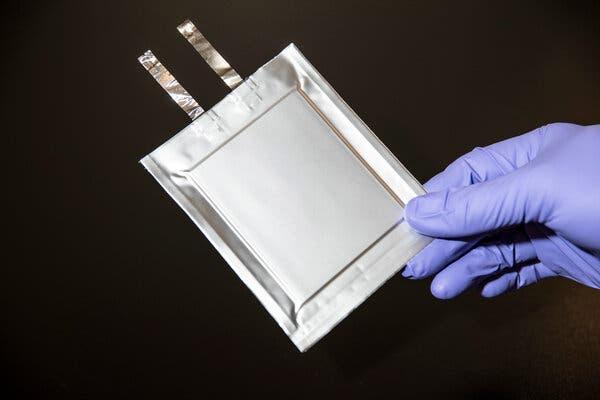

Sodium-ion battery manufacturing principle

Sodium-ion batteries (SIBs for short) are rechargeable energy storage batteries that have the advantages of high capacity, light weight, low heat generation, low self-discharge, and low cost. The developed SIBs device can replace traditional Graphene lithium batteries will vigorously promote human recycling energy utilization.

Generally speaking, the working principle of SIBs is as follows: during charging/discharging, the concentration of Na+ on the electrodes of SIBs increases/decreases, and with the application of loads and changes in their electrodes, charge oxidation/reduction ultimately generates hydrogen bonds. These reactions are completed by two opposite containers of the electrochemical cell. One opposite container contains Na+ electrolyte, and the other opposite container contains electrode liquid.

In order to meet the current high capacity and volume requirements of electronic products, researchers tend to use curved electrodes to reduce the battery size of SIBs. Compared with other lithium-ion battery types, curved electrodes can transfer Na+ between two containers more efficiently. SIBs can also be improved into nano-copolymer electrodes, which ensures the high capacity and constant capacity performance of the battery during precision processes.

20 pros and cons

advantage:

1. Sodium-ion batteries have higher capacity and can store more energy, making them more conducive to large-capacity applications;

2. SIBs are smaller in size and lighter in weight, which can save space and weight;

3. Has good heat resistance and high temperature stability;

4. Small self-discharge rate, more durable energy storage;

5. SIBs have better safety than other batteries and are less likely to ignite in liquid polarization;

6. It has good recycling ability and can be reused many times;

7. SIBs have low cost and save material costs in production.

shortcoming:

1. SIBs have a low voltage under normal conditions and are not suitable for use in high-voltage applications;

2. SIBs usually have high conductivity, resulting in low charge and discharge efficiency;

3. The internal resistance is high, and the charging and discharging processes will cause great losses;

4. The electrode material is unstable and difficult to maintain for a long time;

5. Batteries sometimes have a higher failure rate under high temperatures and harsh conditions;

6. The reduced capacity of SIBs will cause greater losses during circulation;

7. Not all electronic products can use sodium-ion batteries. For example, some devices need to maintain a certain input voltage before they can work properly.